ROBOTIC DUAL-ARM SOLUTIONS FOR SHOT BLASTING CUNSTRUCTIONAL STEEL

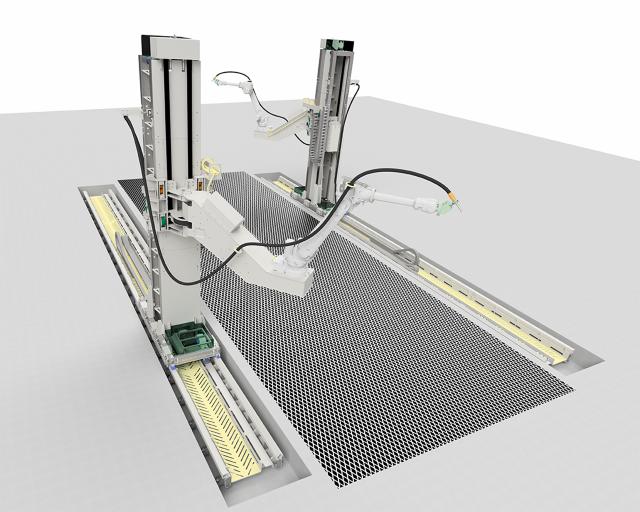

Clemco Denmark's Dual robotic solutions for shot blasting featuring two synchronized robots that blast in parellel and has a very good blasting coverage of large steel structures.

Designed for longevity, this system operates continuously in demanding industrial environments with minimal upkeep. Its modular and adaptable design supports steel structures of various sizes and shapes, ensuring flexibility for a wide range of surface treatment needs.

Advantages of Using Dual-Arm Robotic Solutions for Shot Blasting Constructional Steel Items

Our robotic system is based on two parallel industrial robots on external axes with an effective reach to cover larger steel structures with relatively complex geometries.

By implementing our dual-arm robotic solution for shot blasting constructional steel items, companies can achieve higher productivity, superior surface preparation quality, and improved operational efficiency, all while enhancing safety and sustainability.

Improved Access to Complex Surface

- By using two parallel robots for sandblasting, the system can cover a fairly large area while avoiding any obstacles on the structure.

Consistent and Uniform Treatment

- Both robotic arms work in perfect synchronization to deliver precise and uniform shot blasting across the entire surface.

- Eliminates variability in treatment quality compared to manual processes.

Increased Productivity

- The robotic system can blast sand efficiently with two 19 mm nozzles, providing a productivity of approximately 60 to 90 m2 pr h depending on the degree of cleaning.

Enhanced Flexibility

- The system is adaptable to handle steel items of different shapes, sizes, and complexities.

- Programmable control allows for rapid adjustment to meet varying production requirements.

Optimized Material Usage

- Precise control of abrasive flow minimizes waste and ensures efficient use of blasting materials.

- Reduces operational costs while maintaining high-quality surface preparation.

- Reduces energy consumption for compressors as air consumption is optimized for shot blasting which is performed in a continuous and repeatable process that does not overblast the surface.

Superior Quality Control

- Integrated sensors and monitoring systems ensure consistent blasting parameters and uniform surface preparation.

- Achieves superior results that meet stringent industry standards.

- The uniformity of sandblasting is very consistent when sandblasting is done robotically compared to a manual sandblasting process.

Improved Worker Safety

- Automates the blasting process, removing operators from hazardous environments with dust, noise, and debris.

- Enhances workplace safety and reduces physical strain on workers.

Durability and Reliability

- Designed for heavy-duty industrial use, the system provides reliable performance with minimal maintenance.

- Capable of operating in demanding environments without compromising quality.

Environmental Benefits

- Robotic performed blasting reduces the blasting material waste, minimizing environmental impact.

- Enclosed systems allow for abrasive recovery and recycling, supporting sustainable operations.

Robotic Features

Our advanced dual-arm robotic solution for shot blasting large constructional steel items is engineered to deliver precision, efficiency, and reliability in surface preparation for anti-corrosion treatments. Featuring two synchronized ABB robots on 2 or 3 external servo axes, the system ensures uniform and consistent blasting coverage, even on complex geometries and hard-to-reach areas.

Equipped with advanced motion control and programmable automation, the system ensures precise robotic adjustments and consistent blasting parameters across all surfaces. Integrated sensors and real-time process monitoring guarantee a uniform abrasive flow, reducing material waste while maintaining superior quality.

Built for durability, the system is capable of operating continuously in demanding industrial environments with minimal maintenance. Its modular and adaptable design accommodates steel structures of varying sizes and shapes, providing flexibility for diverse surface treatment requirements. The enclosed blasting environment supports efficient abrasive recycling, reducing waste and enhancing sustainability. This cutting-edge solution ensures the highest standards of performance, making it ideal for preparing steel components for anti-corrosion coatings.

GET IN TOUCH WITH OUR EXPERTS

If you are looking to optimize surface preparation for large constructional steel items, our advanced dual-arm robotic solution for shot blasting offers unmatched precision and efficiency. Designed to prepare steel structures for anti-corrosion treatments, this synchronized dual-arm system ensures consistent coverage, improved access to complex surfaces, and superior blasting quality.

To learn more about how our innovative robotic technology can enhance your production processes, reduce operational costs, and ensure top-tier results, get in touch with our team of experts. We are ready to provide technical insights and tailored solutions to meet your specific needs. Contact us today to discover how we can help you elevate your surface treatment operations.

From delivery to production

Installation and commisioning

Our site supervisors are responsible for installation in close collaboration with the engineering team and the customer’s team on site. By using our own supervisors, we ensure that the installation is carried out according to the design drawings and the in-house quality tests.

We set up the complete process line and supervise all installation tasks. We have the necessary insurance and permits for the installation of epoxy and polyurethane systems and are able to accommodate most HSSE requirements during the work. In addition, we offer a full CE approval of the entire solution.

Full documentation package

When our technical department develops technical solutions for our customers, the documentation package is just as important as the actual product.

The documentation package is performed according to the standards and certifications applicable for the specific product or country.

Service and maintenance

Clemco Denmark has a highly skilled service department with experts in surface treatment equipment and robotic solutions. Part of our documentation package is delivering a complete spare part lists and expected life spans on consumable parts that are included in the service program. We guarantee that spare parts are available during a certain lifetime. In addition, Clemco Denmark provides personal protective equipment for operators, and we have a large inventory of different spare parts.

Training of operating personnel

Part of commissioning is training the operators and technicians in operating the robotic system. We also carry out training in correct maintenance of the installation and replacement of key components.

We introduce the individual procedures to respect the agreed transfer efficiency rates and process time. It is an essential part of our project management that a thorough hand-over of the system is carried through.